Refrigerants: Managing with Carbon Dioxide & Ammonia (EN)

The dairy industry relies on progressive solutions involving carbon dioxide, and ammonia in a bid to combat climate change.

By Dr. Karin Jahn Managing Director, eurammon

IN February 2007, the Intergovernmental Panel on Climate Change (IPCC) presented its climate report. This report predicts that the mean global temperature of the lower atmosphere will rise by about 3°C. by the year 2100. The consequences include the melting of the Greenland Ice Sheet and Arctic ice, rising sea levels, and increases in extreme weather conditions. The only way to skew climate v change is by cutting greenhouse gas emissions.

“For refrigeration, this means giving priority to natural refrigerants,“ says Monika Witt, CEO of eurammon, the European initiative for natural refrigerants. “Either they make no contribution at all, as in the case of ammonia, or a negligible contribution, as in the case of carbon dioxide or hydrocarbons, to the greenhouse effect.

“The fact that the use of carbon dioxide in refrigeration is considered environmentally compatible may seem surprising at first but the quantities and the amount of energy used in producing it are so small when compared to worldwide carbon dioxide emissions that they would pale to insignificance in the climate statistics.”

WORLD’S FIRST CARBON Dioxide Freezer

One of the first companies to opt for carbon dioxide as a natural refrigerant is the food and beverages giant Nestlé, which beyond mineral water, baby food and coffee, is especially well known for its ice cream products.

Nestlé operates a large ice cream factory in Bangchan, Thailand. To meet the growing demand for Nestlé’s brands, Nestlé Thailand needed to extend its Bangchan ice cream factory and increase production capacity. This also involved the refrigeration units, which still used the synthetic refrigerant HCF-22.

In line with Nestlé’s environmental sustainability policy, natural refrigerants were to be given preference. In cooperation with Johnson Controls Inc (formerly York Refrigeration International) and Gram Equipment A/S, Nestlé engineers installed the word’s first commercial ice cream freezer using carbon dioxide.

The freezer surpasses the efficiency of conventional freezing solutions. In addition to the new freezer, Nestlé also installed a new freezing tunnel, which is used to harden ice cream. The refrigeration required by the tunnel is provided by a capacity cascade system containing an ammonia and carbon dioxide cycle.

Nestlé put both of these new facilities into operation in 2005/2006, setting new standards for the use of natural refrigerants in the Asia~Pacific region: This is well ahead of what was required by the Montreal protocol for developing countries such as Thailand, where HCFC phaseout is not due until 2040.

MAXIMUM COOLING OUTPUT

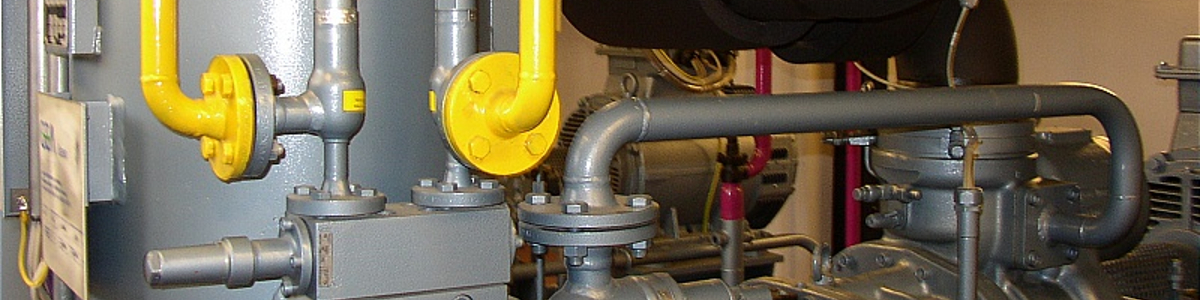

Unilever has built a high efficiency ammonia – based refrigeration plant in Prague, where the consumer goods manufacturer has, its Czech headquarters, which encompasses numerous production and administrative buildings. Because the margarine arid edible tats unit, which produces brands such as Rama and Flora, needed to expand, the company needed a new store at short notice.

The aim was to minimise the refrigerant charge while maximising the cooling output. So the Czech contractor Bohemiachlad implemented a central dry expansion ammonia plant, which has a refrigerant charge of just 100 kg. Ammonia is only used in the machine room, while the chill store is refrigerated using water as a coolant. The chilier provides cold water at 3°C, which warms to about 10°C in the wake of the cooling process. Among the main components of the plant are three screw V compressors, variable speed compressors, plate heat exchangers and condensers. The coolant evaporating temperature is 0°C, and the condensation temperature is 35°C. The two megawatt Chiher is one of the largest plants in Europe. All of its processes are centrally controlled and monitored by a computer-aided control system.

COOLING ENERGY

The German contractor Kältetechnik Dresen + Bremeifl GmbH built a single~stage pumped~ammonia refrigeration system with an ice water silo for crushed ice for the Nordmilch eG dairy. At the heart of the facility in Beesten‘ Lower Saxony/ Germany, are two Grasso screw compressors which are installed together as a so-called Duo-Pack on a shared frame.

The entire cooling system is fined with 2,700 kg of ammonia and has a maximum refrigerating capacity of 1200 kilowatts for direct cooling of ice water or for making crushed ice. The coolant evaporating temperature is 2°C for direct cooling and 6°C for ice making. The condensation temperature is 35°C. The ice is made at night and at off-peak times by three trickle coolers and is then stored as cooling energy in a silo, or ice bank.

During the day, three pumps are used to pump ice water, that is about 0°C to 1°C in temperature, to where it is needed for the production processes, for example to cool the raw milk that just been delivered. The: chilled water, which by that time has been warmed up, is then cooled again in an ice water precooler, before. being returned to the ice-bank. The trickle coolers are also used for direct water cooling as well as for ice making.

Using the crushed ice beam? Nordmiich can, on the one hand, take advantage of the cheaper off peak electricity and, on the other, reduce peaks in power consumption. A key advantage of this plant’s method of using a crushed ice bank is the ability to attain a very high melting rate thanks to the high contact surface area of the crushed ice in the ice bank. Indeed, the operator has repeatedly confirmed that the ice. water supply temperature never excess 1°C, even though the load is now twice what the system was originally designed for.

USING ICE WATER

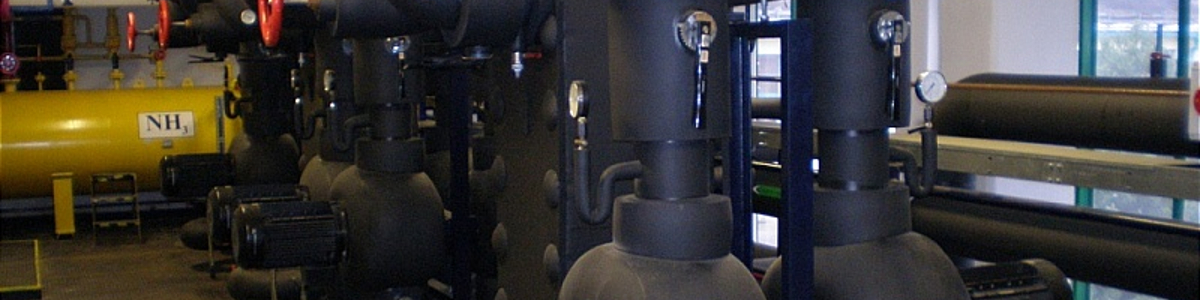

The Sachsenmilch AG dairy was; also seeking ways to save money by reducing the high power costs incurred by cooling and refrigeration. So Johnson Controls Systems & Service GmbH (formerly York Deutschland GmbH) designed an ice water pre-cooling plant for its headquarters in Leppersdorf, Saxony/Germany.

This allows the warmed water, returning from the cooling system to be cooled to 1°C before it is returned to the ice water tank‘ reducing the load on the system. A key component of the ice water pre-commg system are Sabroe screw compressors. which have a refrigeration capacity of 2,400 kilowatts each.

They use ammonia, with a charge of less than 750 kg per unit. The evaporating temperature is ~1.5“C and the condensation temperature is 35°C. The evaporator is a gravity driven plate heat exchanger fitted with a separator. This improves the afficiency vs. direct expansion systems, which again cutS operating expenses. Other components include a 3,000 kilowatt evaporative condenser as well as a heat dissipator and oil coolers for recovering waste heat.

Complex PLC controls ensure that the temperature of the ice waters fluctuates by no more than 0.5°C. So far, Johnson Controls Systems & Service has installed four such cooling systems for Sachsenmilch. with a total refrigeration output of 9,600 kilowatts.

These examples clearly show that plants using natural refrigerants are not only better for the environment, but also cut overhead. costs,“ says eurammon‘s Monika Witt. “Because ammonia and carbon dioxide are very efficient, it was possible to achieve the required refrigeration output much more economically in every case. For the operators, this means energy savings of up to 30 percent.”

For more information, ENTER No: 0650

Pivovar Ostravar modernizoval své nejpřísněji střežené zařízení – spilku (CZ)

Ostravský pivovar v těchto dnech modernizuje spilku, jednu z nejdůležitějších částí svého pivovaru. „Zatímco varna představuje srdce pivovaru, na spilce se z mladiny vyrobené na varně stává alkoholický nápoj, což je v procesu výroby piva samozřejmě klíčový okamžik,“ podtrhuje význam investice vrchní sládek pivovaru Ostravar Richard Kornas. Celá modernizace spilky, která bude dokončena v březnu, […]

Read moreNapsali o nás v magazínu Czech Business & Trade (EN)

Bohemiachlad – Partner to Demanding Clients Seeking the Best in the Area of Cooling Devices Bohemiachlad, s.r.o., Praha, a purely Czech company, which has been in the market for more than 20 years, offers designs, projects, deliveries, and realisation of cooling equipment targeted to energy savings and minimization of the use of coolants. “We offer […]

Read moreRefrigerants: Managing with Carbon Dioxide & Ammonia (EN)

The dairy industry relies on progressive solutions involving carbon dioxide, and ammonia in a bid to combat climate change. By Dr. Karin Jahn Managing Director, eurammon IN February 2007, the Intergovernmental Panel on Climate Change (IPCC) presented its climate report. This report predicts that the mean global temperature of the lower atmosphere will rise by […]

Read more